Company Introduction

Blueview Elec-optic Tech Co., Ltd. – Architecture Lighting Division

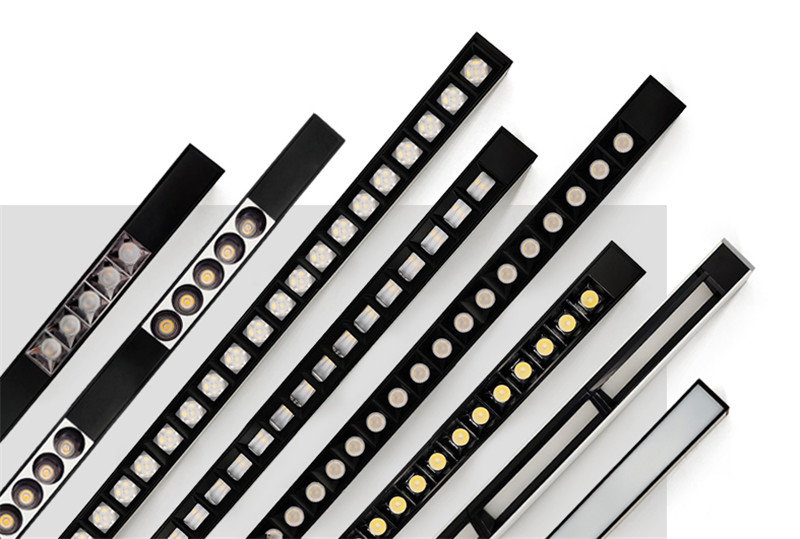

BVInspiration, a dynamic sub-division of Blueview established in 2016, is a leading force in the realm of commercial architectural and acoustic luminaires. With an unwavering commitment to excellence, we stand at the forefront of the industry, delivering unparalleled service and designing high-quality products that redefine standards and elevate spaces.

Our unwavering vision centers on making the world a better place. Through innovative solutions and cutting-edge designs, we aim to create environments that inspire, uplift, and transform. We take pride in our ability to forge strong and enduring partnerships with our valued clients, understanding their unique requirements and tailoring our offerings to exceed expectations.

ChengDu Headquarters

PuJiang Production Base

ZhongShan Production Base

Innovation

At BVInspiration, innovation is ingrained in our DNA. We consistently push the boundaries of creativity and forward-thinking to develop luminaires that not only meet the latest trends but also set new ones. Collaborating closely with our clients and stakeholders, we bring together functional and aesthetic advantages, leaving lasting impressions on every project we undertake.

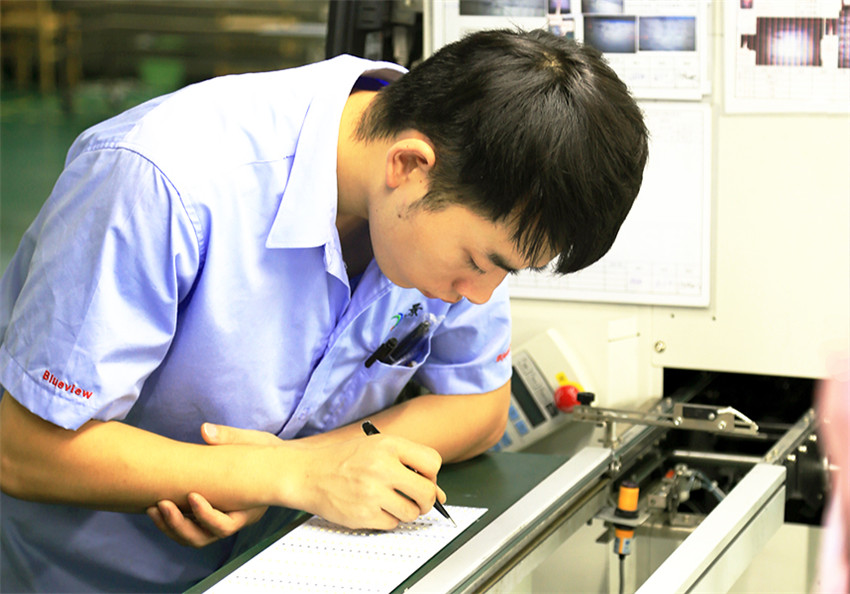

Craftsmanship and precision are the cornerstones of our work. Each of our products is meticulously designed and engineered with a focus on captivating design, effortless installation, user-friendly operation, and easy maintenance, ensuring a seamless experience for our clients and end-users alike.

CAPABILITY

Seamless Communications

Via our professional customer service, we provide excellent quality communication and after-sales support. Our customer service group is a cadre of highly-trained lighting professionals, able to communicate fluently in English and Chinese regarding our engineering and manufacturing processes and the technical field of lighting. One of these customer service representatives is assigned to work with each of our clients.

That person is the client's representative at BVI, working in close partnership with our client and responsible for answering every question, from design and manufacturing issues through quotation and accounting concerns. We stay in contact with our clients via Teams, Zoom, WeChat, and conference calls as well as through email and fax.

Contract Engineering

BVI Engineering develops lighting, electronics and industrial products for US, European and Asia market, undertaking projects of all sizes and complexity. Whether the product is a new idea or the redesign of existing product, our experienced engineers can take our client's ideas from concept to a finished, marketable product.

Our industrial designers create collections of lighting fixtures for our clients upon request. In recent years we have created many successful architectural and decorative lighting fixtures.

Contract Engineering

We have a very talented R&D engineering group specializing in designing LED products. BVI not only can build per client's exact specifications and BOM, but can also take in "sketch" designs or hand samples, and create a mature product for the client to take to market.An integral part of product design and manufacture is the testing of materials and luminaires. BVI has TUV authorized test laboratories with equipment that can test luminaire.

Industries Served:

Lighting, Electronics

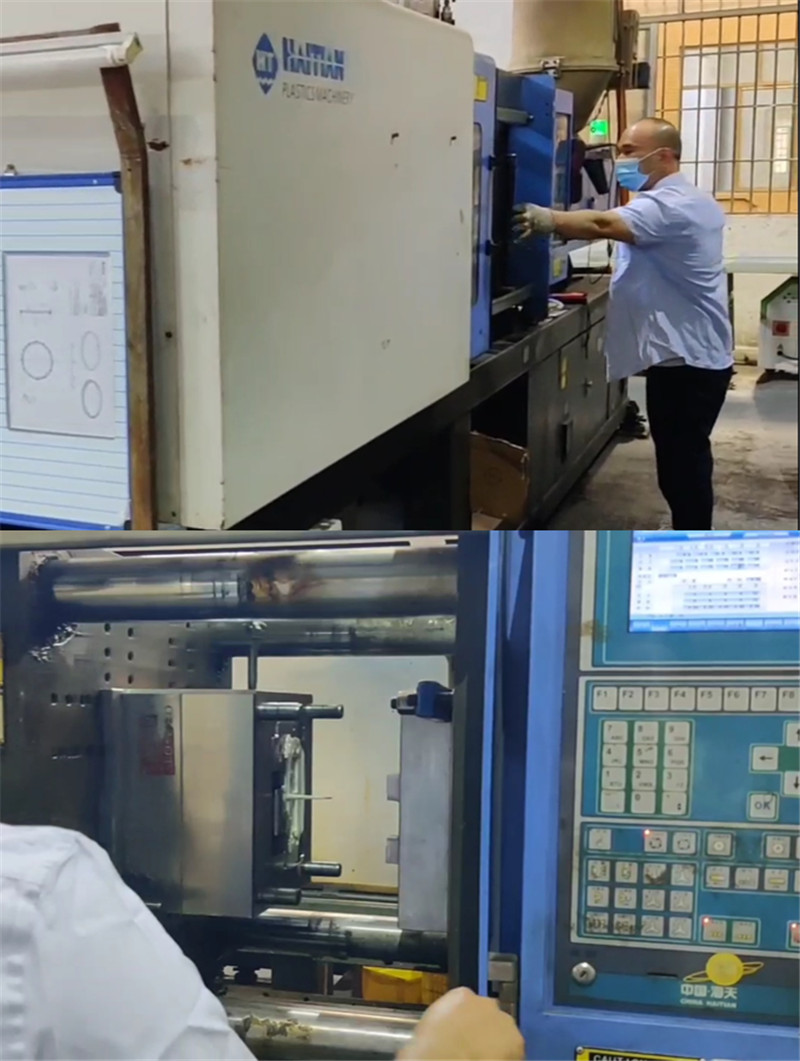

As a lighting and industrial products manufacturer, BVI's primary manufacturing industries are as follows: Die casting and powder coating, Precision machining, Metal working and painting. We also maintain permanent mold, deep draw, spinning, injection molding, welding, to support our manufacture of luminaires, lighting sub-assemblies and other industrial components.

Quality Assurance

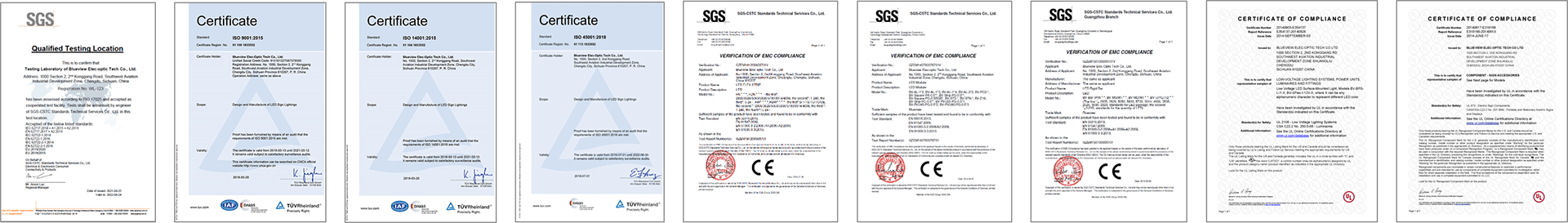

The factory is certified under ISO 9001:2015 standards. As a leading manufacturer of lighting and industrial products, BVI specializes in various manufacturing processes, including die casting, precision machining, metalworking, powder coating, painting, permanent mold casting, deep draw, spinning, injection molding, and welding. These capabilities support the production of luminaires, lighting sub-assemblies, and various industrial components.

R&D

We take quality and compliance seriously, with an SGS-authorized testing laboratory on-site. Our operations and environmental management adhere to ISO standards, ensuring rigorous oversight. Our products hold CE,CB certifications, demonstrating compliance with European, Middle East standards.

Design

Do you have a lighting fixture concept in mind?

At BVI, we house a team of over 12 experienced lighting engineers, with a total of 69 professionals across our two facilities, dedicated to turning your lighting ideas into reality. Whether you have a rough sketch or a vision, our design engineers can assist you in creating a comprehensive blueprint, offering expert guidance on materials and electronics to achieve the desired aesthetics and functionality. With over 80 patents spanning luminaire design and performance, we invite you to bring your concept to BVI—allow us to demonstrate the transformative solutions we can provide for you!"

Prototyping

BVI takes pride in our in-house die casting die manufacturing capabilities and strategic partnerships with trusted 1st tier suppliers for various essential lighting components. Equipped with a diverse range of machinery, including machining centers, wire cutting machines, CNC lathes, mills, and automatic turret presses, BVI possesses the agility to prototype a wide variety of lighting metal parts without the need for specialized tooling.

Our dedicated jig design teams, integrated into each facility, collaborate closely with our machining and die manufacturing groups. They expertly craft fixture devices to ensure that critical parameters such as straightness and flatness are meticulously maintained throughout downstream production processes.

Die-Casting

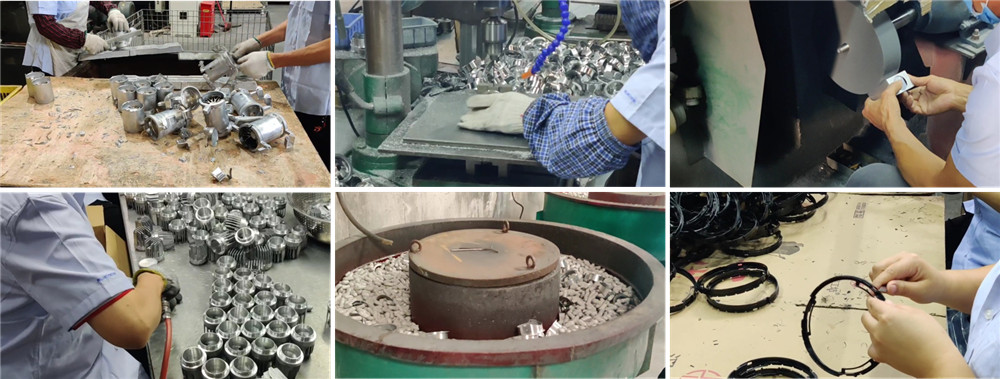

Die Casting is one of BVI's primary in-house manufacturing processes. We have extensive experience in casting many different aluminum and zinc product. BVI utilizes industry-leading melt and pours processes to ensure a strong and ductile die casting that performs well in any environment. We build our casting dies in-house, ensuring that BVI's casting dies are robust and well-designed.

In this ISO 9001:2008 Certified facility BVI produces die cast parts. We pour A360 and A380 aluminum as well as Zinc and brass. Our die-casting machines range in size from 160T to 650T.

Die-Casting Cleanup

We also provide polishing, trimming, sanding, and other die-casting cleanup services on site, and there is also a machining shop where we drill and tap holes, add punched or milled features, or otherwise process die castings as required by the application.

Precision Machining

Precision machining is one of BVI's primary production processes.

BVI produces CNC turnings, precision-machined die castings and extrusions and other types of precision machined products for the lighting.

Assembly

BVI assembles lighting fixture sub-assemblies and complete luminaires for United States and Europe brands. We are experienced in building Architecture lighting, Commercial Lighting, and Low voltage lighting. We maintain clean rooms in our facilities for assembling LED products.

We are offering Powder Coating in house. processes are embedded in-house. Also, we are offering wet spray painting, various oil and chemical-based anodizing, plating, and polishing with outsources.

Product Reliability Testing

We boast a comprehensive inventory of more than 60 state-of-the-art inspection, testing, and measurement tools, dedicated to upholding the reliability of our raw materials and newly developed R&D products. Our equipment portfolio includes precision instruments such as goniometers, photometric spheres, X-ray testers, RoHS testers, 2-dimensional measuring devices, IP testers, package drop testers, and tensile testing machines, among others. These cutting-edge tools ensure the utmost quality and performance of our offerings.

MAKE THE RIGHT LIGHT